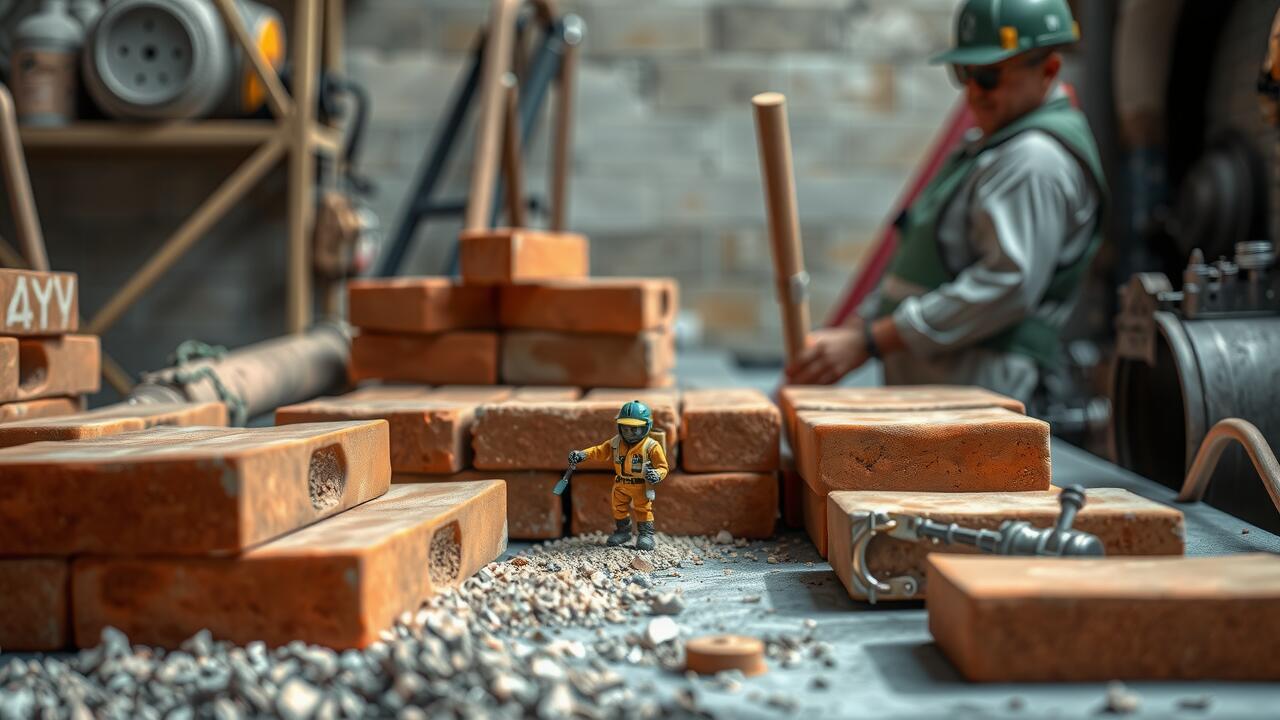

Lubrication For The Brick Making Industry

Selecting the Right Lubricant for Your Needs

Choosing the appropriate lubricant is crucial for optimizing equipment performance and prolonging lifespan. Various factors influence this decision, including the operating environment, load specifications, and machinery type. Understanding the specific requirements of your machinery ensures the selected lubricant effectively reduces friction and wear, thus enhancing overall efficiency.

Additionally, the compatibility of the lubricant with existing brick systems cannot be overlooked. Different lubricants have varying formulations that can affect their performance characteristics. Evaluating temperature ranges, potential for contamination, and the presence of any specific additives will help in making a well-informed choice. Tailoring the lubrication strategy to meet specific operational needs ultimately leads to better machine functionality and reduced downtime.

Factors to Consider When Choosing

Selecting the appropriate lubricant involves evaluating several crucial factors tailored to specific applications. Viscosity is often a primary consideration, as it influences how well the lubricant can reduce friction and wear. Options range from low to high viscosity oils, impacting flow rates and protective capabilities. Furthermore, the lubricant's chemical compatibility with materials in contact, such as seals and metals, ensures long-lasting performance without damaging components.

Environmental conditions play a significant role in lubricant selection, especially in harsh operating environments. Factors like temperature extremes and exposure to moisture or corrosive substances dictate the formulation needed to maintain effectiveness. Additionally, the intended operating speed of machinery must be considered, as high-speed applications typically require specially designed lubricants to perform effectively without breaking down. Overall, a thorough assessment of these factors helps in choosing the right lubricant for optimal efficiency and longevity.

Common Lubrication Challenges in Brick Production

In brick production, lubrication plays a critical role in the efficiency of machinery and the overall quality of the final product. High temperatures encountered during the brick-making process can cause conventional lubricants to break down quickly. This breakdown not only compromises the effectiveness of the lubricant but also increases wear and tear on equipment, leading to potential failures and costly downtime.

Dust contamination presents another significant challenge in the lubrication process. The brick production environment is often filled with abrasive particles that can infiltrate lubrication systems. This contamination can result in the degradation of both the lubricant and the machinery, causing operational issues that hinder productivity. Proper selection of lubricants and advanced filtration systems are essential to combat these challenges and ensure optimal performance in brick production.

Addressing High Temperatures and Dust Contamination

High temperatures in brick production processes can significantly affect the performance of lubricants. Choosing a lubricant that has a high thermal stability is essential to ensure it can withstand the extreme conditions without breaking down. Such lubricants not only lower friction but also protect machinery components from wear due to heat-induced degradation.

Dust contamination poses additional challenges, as it can interfere with the proper functionality of lubricants. Implementing effective sealing solutions and utilizing dust-resistant lubricant formulations can mitigate this issue. Proper maintenance routines, including regular inspection and cleaning, help maintain ideal operating conditions and prolong the lifespan of both the lubricants and equipment.

The Role of Lubrication in Quality Control

Maintaining high standards in brick production hinges on an effective lubrication strategy. Quality control relies on consistent operations, as even minor fluctuations can result in defects. Proper lubrication minimizes wear and tear on machinery, ensuring smooth functioning. This reliability helps in maintaining uniform pressure and temperature during the production process, which is crucial in producing bricks that meet industry standards.

Another aspect of lubrication's role in quality control is its influence on the production cycle. When machines operate efficiently, they minimize downtime and waste, directly impacting the overall quality of the bricks. Any lapse in lubrication can lead to equipment failure, creating inconsistency in the output. Therefore, investing in the right lubrication solutions not only enhances operational efficiency but also upholds the integrity of the final product.

Ensuring Consistency in Brick Production

Quality control is essential in the brick production lubrication process, as it directly impacts the final product's durability and reliability. Consistency in the lubrication application contributes significantly to maintaining uniform performance across production lines. Proper lubrication mitigates wear and tear on machinery, preventing fluctuations in equipment efficiency that could lead to inconsistent brick quality.

Effective lubrication practices help ensure that each batch of bricks meets established standards. The right lubricant selection plays a crucial role in minimizing variations that could arise from factors such as temperature changes or machinery malfunctions. By monitoring lubrication levels and optimizing the application frequency, manufacturers can achieve a stable production environment that fosters high-quality outcomes.

Innovations in Lubrication Technology

Recent advancements in lubrication technology have focused on enhancing performance while reducing environmental impact. Biodegradable lubricants are gaining traction, offering a sustainable alternative to traditional petroleum-based options. These products are designed to provide superior lubrication under demanding conditions, ensuring machinery operates efficiently and with minimal ecological footprint. Innovations in formulations are frequently tested for their effectiveness in high-load applications, resulting in options that can withstand extreme pressures and temperatures.

Another area of development involves smart lubrication systems that utilize sensors and connectivity features. These systems provide real-time monitoring of lubrication levels and performance, allowing for proactive maintenance that can prevent equipment failures. Automatic dispensing technologies can ensure that the right amount of lubricant is applied exactly when needed, minimizing waste and downtime. Together, these innovations not only enhance the reliability of equipment in heavy industries but also contribute to cost savings through improved maintenance practices.

Advancements to Improve Performance

Recent developments in lubrication technology have focused on enhancing efficiency in various applications. These advancements include the use of synthetic lubricants designed to withstand extreme conditions while minimizing friction and wear. By employing nanoparticles, manufacturers can create lubricants that offer superior performance, which is especially beneficial in high-load scenarios.

Another exciting trend involves the integration of smart technology into lubrication systems. Sensors and monitoring devices are being utilized to track lubricant conditions in real-time, allowing for timely adjustments and reducing the risk of over- or under-lubrication. This proactive approach not only extends equipment life but also optimizes operational efficiency, making it a valuable addition to modern brick production processes.

FAQS

What type of lubricant is best for the brick making industry?

The best lubricant for the brick making industry depends on specific applications, but generally, high-temperature and dust-resistant lubricants are recommended to withstand the challenging conditions of brick production.

How do high temperatures affect lubrication in brick production?

High temperatures can cause lubricants to break down more quickly, reducing their effectiveness. It's essential to select lubricants designed to maintain their viscosity and performance at elevated temperatures.

What are the common lubrication challenges faced in brick production?

Common challenges include managing high temperatures, dust contamination, and ensuring that lubricants provide consistent performance under varying operational conditions.

How can I ensure consistency in brick production through lubrication?

Maintaining a regular lubrication schedule, selecting the right products, and monitoring lubrication systems can help ensure consistent performance and quality in brick production.

Are there any recent innovations in lubrication technology for the brick making industry?

Yes, recent advancements include the development of synthetic lubricants, improved additives that enhance performance, and automated lubrication systems that ensure precise application and reduce human error.